Physics-Based Packaging Intelligence

The Shift to Primary Packaging Delivery Changes Everything

Stop Guessing. Start Calculating.

Your packaging was engineered for force profiles at the pallet and case level that are increasingly irrelevant. The relentless expansion of primary packaging moving through eCommerce requires a fundamental redesign.

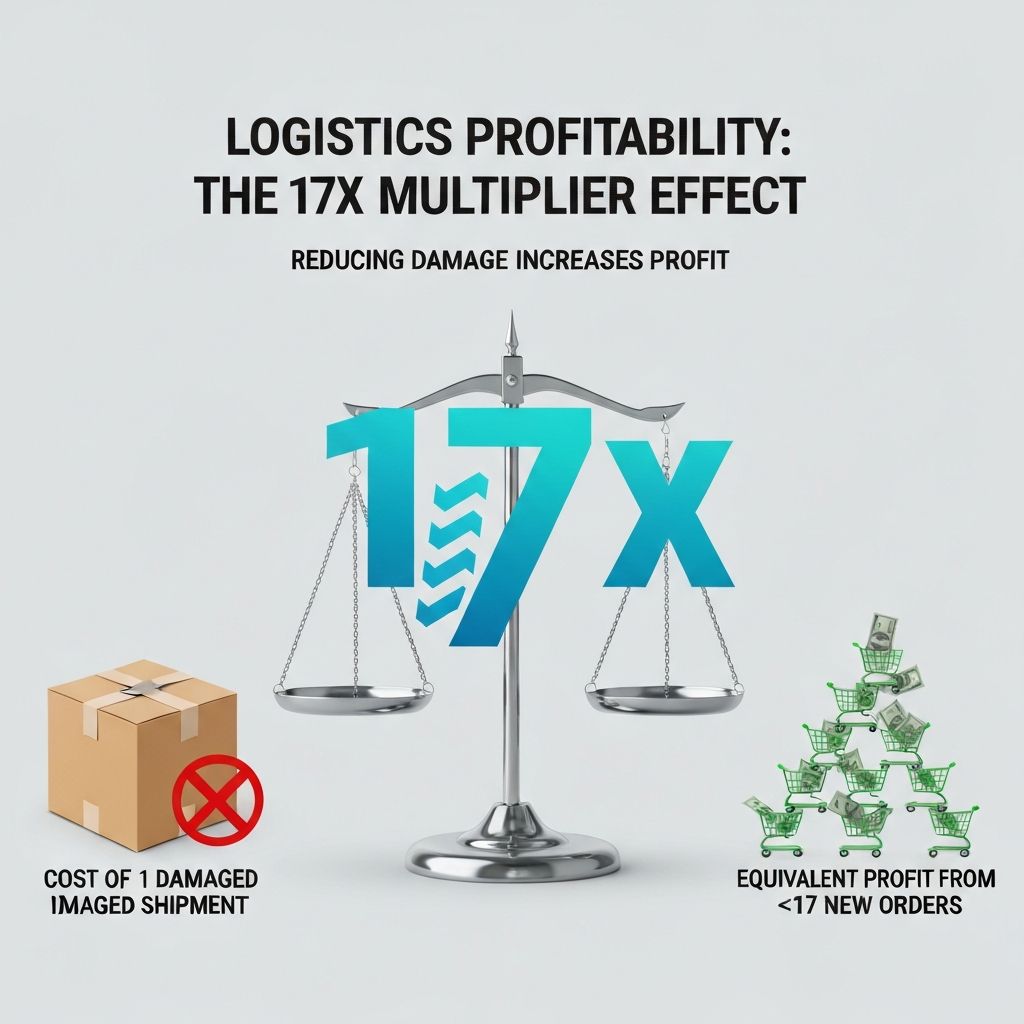

About 50% of consumers switch to a competitor after one bad experience, rising to 80% after multiple failures. Every damaged delivery costs 17x in replacement and customer lifetime value.

Why Primary Packaging Fails in Modern Fulfillment

The problem is not your product. It is that packaging was engineered for force profiles at the pallet and case level that are increasingly irrelevant in a world where primary packaging moves through eCommerce networks.

The Acceleration

Products that once moved safely nested in corrugated cases and stretch-wrapped pallets now ship individually through 3PLs, sortation centers, and last-mile carriers. This acceleration to primary packaging delivery exposes your product to:

Drop heights of 60 inches and more

At sortation and delivery - it is the big drops that cause the damage

Unpredictable orientations

Through automated handling systems

Thermal extremes

In uncontrolled last-mile vehicles

Compression loads

Never designed into primary packaging specs

Around 90% of product damage in the CPG supply chain occurs in the distribution center and retail portion, and eCommerce Packaging 3.0 has made this exponentially worse.

The Physics Gap

Why use statistical approaches when you can use empirical validated information as the baseline?

Your competitors approach this with surveys, customer feedback loops, and iterative testing. They optimize based on damage rates - a lagging indicator that costs you customers before you even know there is a problem.

What is actually needed is understanding the minimum failure energies throughout your fulfillment network and designing primary packaging (or secondary protection) to survive those specific forces. This requires ground truth force data from high-speed acquisition systems deployed in actual supply chains, combined with computational physics. Empirical answers, not guesses.

The Pioneers of Physics-Based Packaging Engineering

Cognify is where computational physics meets real-world packaging complexity. We do not just design packaging; we capture actual force profiles from live supply chains through high-speed data acquisition, then model the exact forces, orientations, thermal profiles, and stochastic variables your products encounter from fulfillment center to customer porch.

Our Lineage

We pioneered the physics-based methodologies that enabled Packaging 2.0 - the era when case-and-pallet distribution demanded predictable, repeatable protection systems. Those same mathematical models, refined over decades of experience across multi-disciplinary team members, now power the solutions for eCommerce Packaging 3.0, pharma drug delivery, and federal supply chain protection applications where failure is not an option.

Our Approach

We start from first principles, stripping complex systems to their fundamental physics, and build solutions using:

Ground Truth Data Collection

High-speed data acquisition systems deployed in your actual fulfillment networks to capture real force profiles, impacts, orientations, and thermal conditions

Computational Analysis

FEA, CFD, multi-body dynamics, thermal modeling validated against empirical data

Hybrid ML/AI Intelligence

Surrogate models that approximate expensive computational simulations, enabling faster exploration of design spaces

Physical Validation

Lab testing protocols that mirror actual network conditions captured through data acquisition, not generic standards

Our Mission

Lead the transformation from legacy packaging assumptions to physics-based, computationally validated solutions that protect products moving in their primary packaging throughout modern fulfillment networks - for CPGs, pharma, eCommerce providers, 3PLs, and federal applications.

What Sets Us Apart

The physics-based approach that enabled reliable Packaging 2.0 started with us. While competitors were running drop tests and hoping for the best, we were building finite element models and predicting failure before the first prototype.

We deploy high-speed data acquisition systems in actual fulfillment networks to capture real force profiles, not assumptions. Accelerometers, load cells, thermal sensors, and orientation tracking provide empirical baselines that feed directly into our computational models.

FEA for structural integrity, CFD for thermal protection, multi-body dynamics for impact modeling, stochastic simulation for variable scenarios, and surrogate modeling for computationally efficient evaluation.

We do not treat machine learning as a replacement for physics; we use it as an amplifier. Physics provides the empirical baseline; all physics-informed ML models outperform their data-driven counterparts.

Competitors iterate based on failure data. We calculate based on physics validated against measured forces from your actual supply chain. The most elegant solutions seem simple in hindsight, once developed through rigorous first-principles analysis.

The same computational methods that protect warfighter equipment, optimize pharmaceutical cold chains, and solve federal FEA/CFD challenges apply directly to eCommerce packaging. Physics does not change; applications do.

Computational Physics for Modern Packaging

Understanding what needs to be done in packaging or protection to deliver the product to the customer undamaged is the fundamental challenge.

eCommerce Packaging 3.0 Solutions

The shift from case-load distribution to individual item fulfillment demands new engineering approaches.

What We Deliver:

- Supply Chain Force Profiling: Deploy high-speed data acquisition to capture actual forces throughout your network

- Minimum Failure Energy Analysis: Quantify exact forces at each network touchpoint

- Primary Packaging Optimization: Strengthen existing packaging based on measured requirements

- SIOC Design: Engineer primary packaging that eliminates secondary protection

The Economic Case for SIOC:

Amazon estimates SIOC can save up to $1.1 billion in packaging materials and transportation costs annually. For individual sellers, savings range from a few cents to several dollars per unit.

Applications:

Consumer products, fragile goods, variable-geometry products, multi-item shipments with interaction dynamics.

Pharmaceutical and Drug Delivery Packaging

Cold chain and controlled substances demand precision thermal and structural protection.

Our Expertise:

- High-speed thermal and environmental data acquisition throughout cold chain

- Thermal modeling for insulation, phase-change materials, and shipping duration

- Regulatory compliance engineering (FDA, DOT, international standards)

- Cost optimization while maintaining validated performance

The Economic Benefit:

Like eCommerce a decade ago, cold chain packaging is over-engineered because minimum thermal requirements are not well understood. We bring computational rigor validated by empirical data acquisition to replace the guesswork, reducing material costs while ensuring validated performance.

ML/AI for Packaging Intelligence

We deploy AI where physics alone cannot deliver sufficient fidelity.

Our Hybrid Approach:

- Ground truth provides the foundation from actual supply chains

- Physics models the behavior with FEA/CFD validated against measured forces

- Surrogate models bridge the gap for rapid design exploration

- ML/AI adds predictive power for stochastic variables

- Operational data integration with client data science teams

Real Results:

- Predictive damage modeling that forecasts failure modes before shipping

- Automated quality control using computer vision plus physics models

- Dynamic packaging recommendations based on product plus destination plus empirical network data

Sustainability Engineering

Sustainability is not a checkbox; it is an engineering constraint that must coexist with protection requirements.

Our Solutions:

- Material substitution analysis: 100% recyclable materials, biodegradable polymers, renewable substrates

- Right-sizing based on physics: Eliminate waste while maintaining calculated protection thresholds

- Closed-loop systems: Returnable packaging engineered for multi-cycle durability

The Market Reality:

Nearly three-quarters (73%) of consumers are open to choosing brands that offer more sustainable packaging. Minimal packaging takes the top spot, valued by 61% of shoppers - aligning perfectly with physics-based right-sizing approaches.

The sustainable packaging market is projected to expand from USD 313.72 billion in 2025 to USD 594.46 billion by 2035.

Federal and Defense Applications

The same computational physics competencies that solve commercial packaging challenges power our work in defense and federal sectors.

Warfighter Packaging

- High-speed data acquisition in field deployment

- Ruggedized containers for field deployment

- Drop, shock, and vibration engineering

- MIL-STD compliance

Advanced Simulation

- FEA for structural analysis

- CFD for thermal management

- Multi-physics coupling

- Physics-informed surrogate modeling

Machine Design

- Packaging converting equipment analysis

- Motion control systems

- Precision robotics

- Real-time sensor integration

The Cognify Process

Discovery and Data Collection

We start by understanding your product, your fulfillment network, and your failure modes. What is breaking? Where? Under what conditions?

Ground Truth Force Profiling

Deploy high-speed data acquisition systems (accelerometers, load cells, thermal sensors, orientation tracking) in your actual supply chain to capture real force profiles at every touchpoint.

Physics Modeling

FEA, CFD, and multi-body dynamics models predict behavior under real-world conditions validated against measured data. We calculate forces, stress distributions, thermal profiles, and failure thresholds.

Surrogate Model Development

Where full-fidelity simulations are too expensive or time-consuming, we construct surrogate models that mimic simulation behavior while being computationally cheaper.

Hybrid ML/AI Enhancement

Where stochastic complexity demands it, we layer machine learning on the physics foundation for predictive accuracy, trained on ground truth data from your network.

Physical Validation

Computational models are validated through targeted testing that mirrors actual network conditions captured through data acquisition, not generic ASTM standards.

Implementation Support

We work across your functional teams (packaging, operations, engineering, procurement) to ensure solutions work in the real world, on your lines, through your networks.

Who We Serve

Consumer Packaged Goods (CPG)

Navigating channel shifts to DTC and hybrid retail models while maintaining product protection and brand experience.

Economic driver: Damage rates directly impact margins

Pharmaceutical and Biotech

Ensuring cold chain integrity and regulatory compliance while scaling to meet direct-to-patient delivery demands.

Economic driver: Compliance failures risk patient safety

eCommerce and 3PL

Optimizing packaging across massive SKU catalogs while reducing dimensional weight charges and damage claims.

Economic driver: Every cubic inch of void fill costs money

Federal and Defense

Meeting MIL-STD requirements for ruggedized packaging that survives extreme handling across global logistics networks.

Economic driver: Mission readiness depends on arrival condition

Unboxed Thinking

Insights on physics-based packaging engineering, eCommerce 3.0, and the future of fulfillment.

Coming Soon

Download: "From Packaging 2.0 to eCommerce 3.0: The Physics That Changed" - A technical guide to understanding why case-load assumptions fail in primary packaging delivery.

Engineer Your Packaging for Modern Fulfillment

Products in primary packaging throughout the delivery journey demand physics-based solutions. Let us calculate your protection requirements.

Stop Guessing. Start Calculating.

Why use statistical approaches when you can use empirical validated information as the baseline? Discover how physics-based engineering transforms packaging performance.